中华传统发酵蔬菜历史悠久、风味独特且种类繁多。制作的基本原理是在自然条件下,借助环境和蔬菜表面的微生物及内源酶,利用蔬菜中的糖类等物质,通过一系列生物化学变化(如碳水化合物代谢、蛋白质水解和氨基酸分解代谢、脂肪分解和脂肪酸代谢等),产生醛类、醇类、酮类、有机酸类等特征性风味物质。同时,由于发酵蔬菜中含有大量生物活性分子[1],因此具有一定的调节肠道菌群平衡,降低胆固醇等功能[2]。正因为其具有独特的风味、质地和营养价值,因此备受消费者的青睐。

传统发酵蔬菜的风味主要由香气和滋味组成,香气主要为挥发性风味物质,一般包含醛类、醇类、酯类、酮类等化合物,有助于发酵蔬菜呈现独特气味;而滋味主要由呈味氨基酸、糖类、有机酸等物质组成[3]。此外,不同的蔬菜原料、加工工艺、微生物种类等均影响传统发酵蔬菜风味物质的组成和浓度,进而影响产品的感官特性和消费者的接受度。本文综述不同中华传统发酵蔬菜的风味轮廓、微生物群落及其代谢途径对风味形成的影响。

1 中华传统发酵蔬菜风味轮廓

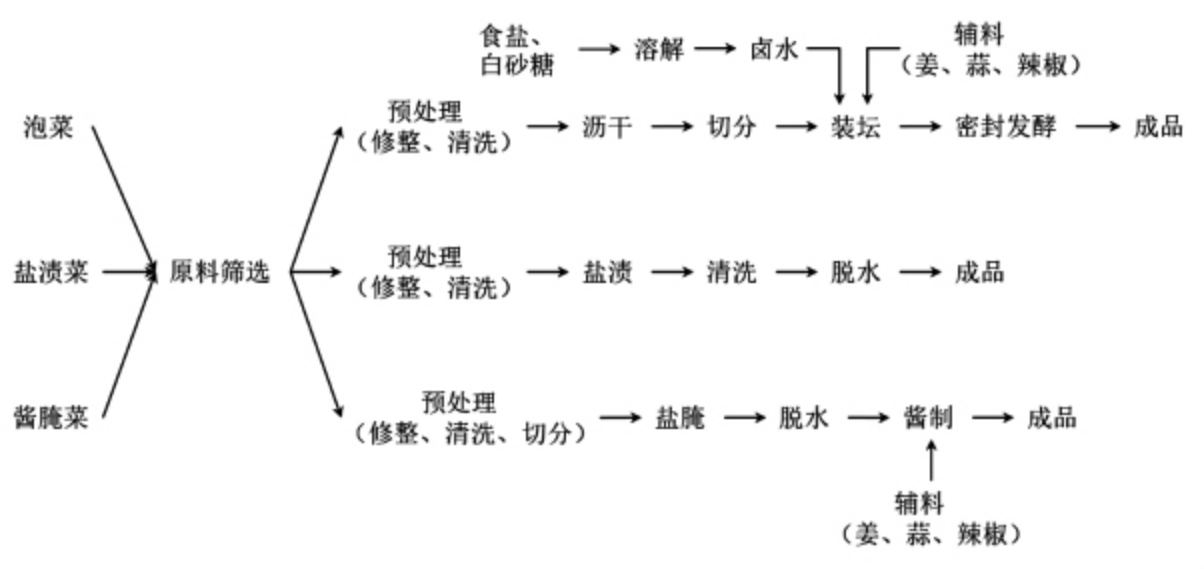

不同的发酵蔬菜产品风味各异,其风味的形成机制随加工工艺的改变而有所不同。根据不同的加工工艺,中华传统发酵蔬菜可分为泡菜类、盐渍菜类、酱腌菜类等(图1)[4],它们的风味物质存在明显差异(表1~3)。通常,当挥发性香气成分的香气活力值(odor activity value,OAV)和味觉活力值(taste activity value,TAV)≥1 时,被认为是传统发酵蔬菜的特征性风味物质[5-6]。

图1 中华传统发酵蔬菜的工艺流程

Fig.1 Process procedure of Chinese traditional fermented vegetables.

1.1 泡菜

泡菜是重要的中华传统发酵蔬菜之一,其富含维生素、矿物质、有机酸和益生菌[7],具有酸味纯正、质地脆嫩、清爽可口、滋味鲜美等特点。其主要以新鲜蔬菜为原料,添加辅料,在中、低含量(2%~10%)的盐水中经乳酸菌和酵母菌等微生物发酵而成的蔬菜食品[8]。微生物利用蔬菜和辅料中的营养物质进行发酵,在各种酶的作用下生成有机酸、游离氨基酸等代谢产物,并合成多种香气成分物质,为泡菜特殊风味的产生提供物质基础[9]。

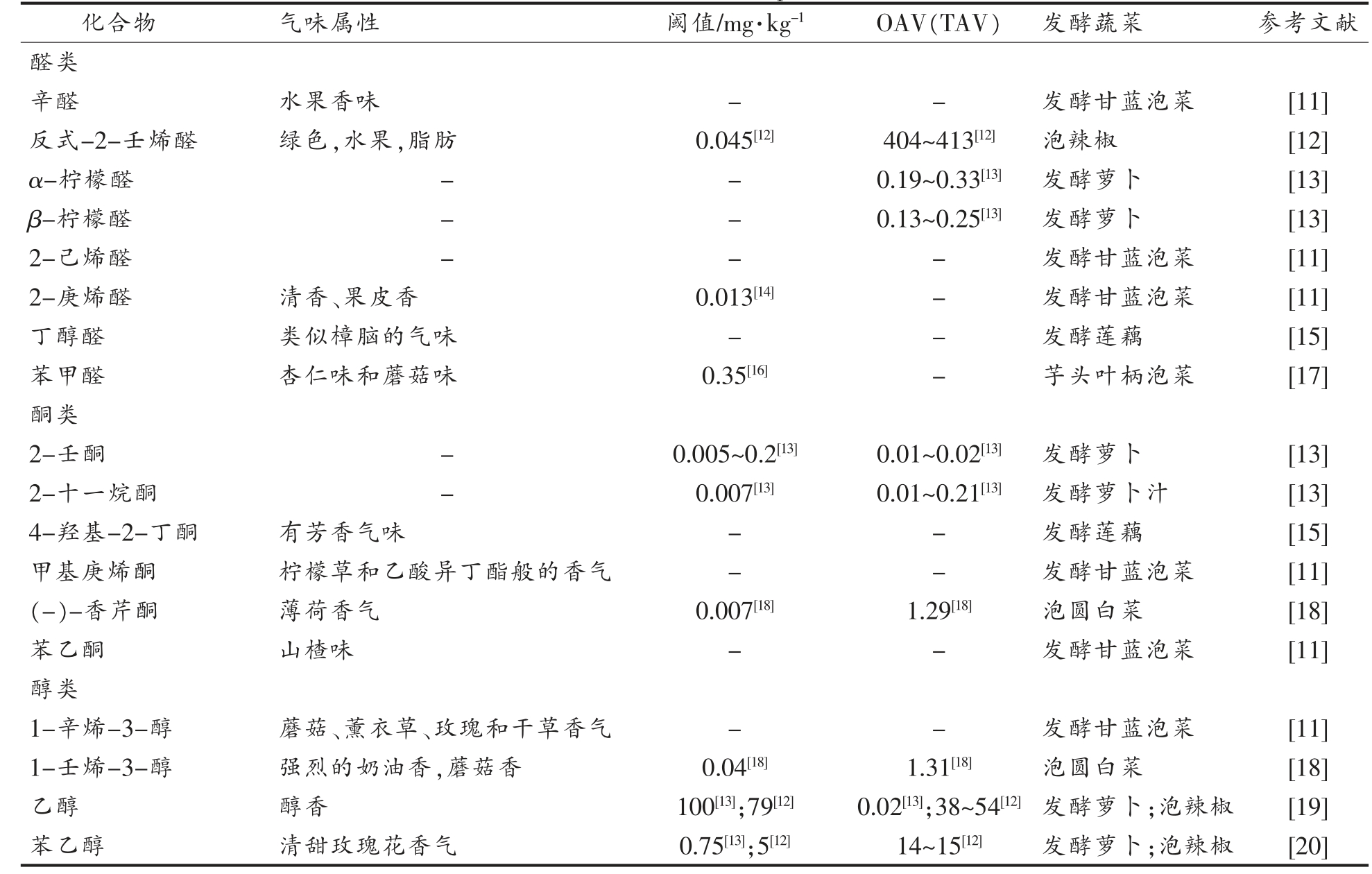

泡菜中主要的发酵微生物有乳酸菌、酵母菌、醋酸菌和霉菌等[10]。通过以上微生物发酵,产生多种风味物质(见表1)。泡菜中的主要风(滋)味物质包括醛类(反式-2-壬烯醛)、酮类【(-)-香芹酮】、醇类(1-壬烯-3-醇、乙醇、苯乙醇、芳樟醇、α-松油醇、2-庚醇、桉叶油醇)、酸类(乙酸、乳酸、苹果酸)、醚类(二甲基三硫醚、烯丙基甲基硫醚)、烃类(β-月桂烯、邻伞花烃、2-异硫氰酸丁烷)、硫化物(二烯丙基硫化物、二烯丙基二硫化物、二甲基三硫化物)等。

泡菜原料丰富,主要有萝卜、莲藕、圆白菜、辣椒,不同发酵蔬菜风味物质不同。泡辣椒中主要风味物质有反式-2-壬烯醛、乙醇、苯乙醇、芳樟醇、α-松油醇、2-庚醇、乙酸,这些物质分别赋予泡辣椒果香、醇香、清甜玫瑰香、花香、紫丁香香气、蘑菇香、刺激性酸味。发酵萝卜中主要风味物质为二甲基三硫醚,具有烂白菜气味。泡圆白菜中主要风(滋)味物质为(-)-香芹酮、1-壬烯-3-醇、桉叶油醇、乙酸、乳酸、苹果酸、二烯丙基硫化物、二烯丙基二硫化物、二甲基三硫化物、烯丙基甲基硫醚、β-月桂烯、邻伞花烃、2-异硫氰酸丁烷,赋予其薄荷香、强烈的奶油香、樟脑味、酸味、洋葱味、大蒜味、熟肉味与清香味。

表1 泡菜主要风味物质

Table 1 Characteristics flavor profile of Paocai

(续表1)

(续表1)

(续表1)

1.2 盐渍菜

盐渍菜是传统发酵蔬菜制品的典型代表,其利用乳酸菌为主的优势本土益生菌群发酵产酸,形成具有“清香、脆嫩、爽口”特点的蔬菜制品。盐渍菜是高盐(含盐量高达13%~15%)、高渗、低pH值的发酵食品,抑制腐败菌生长,耐盐、耐酸微生物生长繁殖,通过发酵作用促进风味物质的形成[30-31]。根据成品形态不同,盐渍菜可分为湿态、半干态和干态3 种。湿态盐渍是指新鲜蔬菜和水一同添加进行发酵,如四川盐渍菜、东北酸菜等;半干态是指加工前不添加水直接进行盐渍,如涪陵榨菜;干态盐渍是指加工前或加工后进行干燥,如萧山萝卜干、宜宾芽菜等[32]。

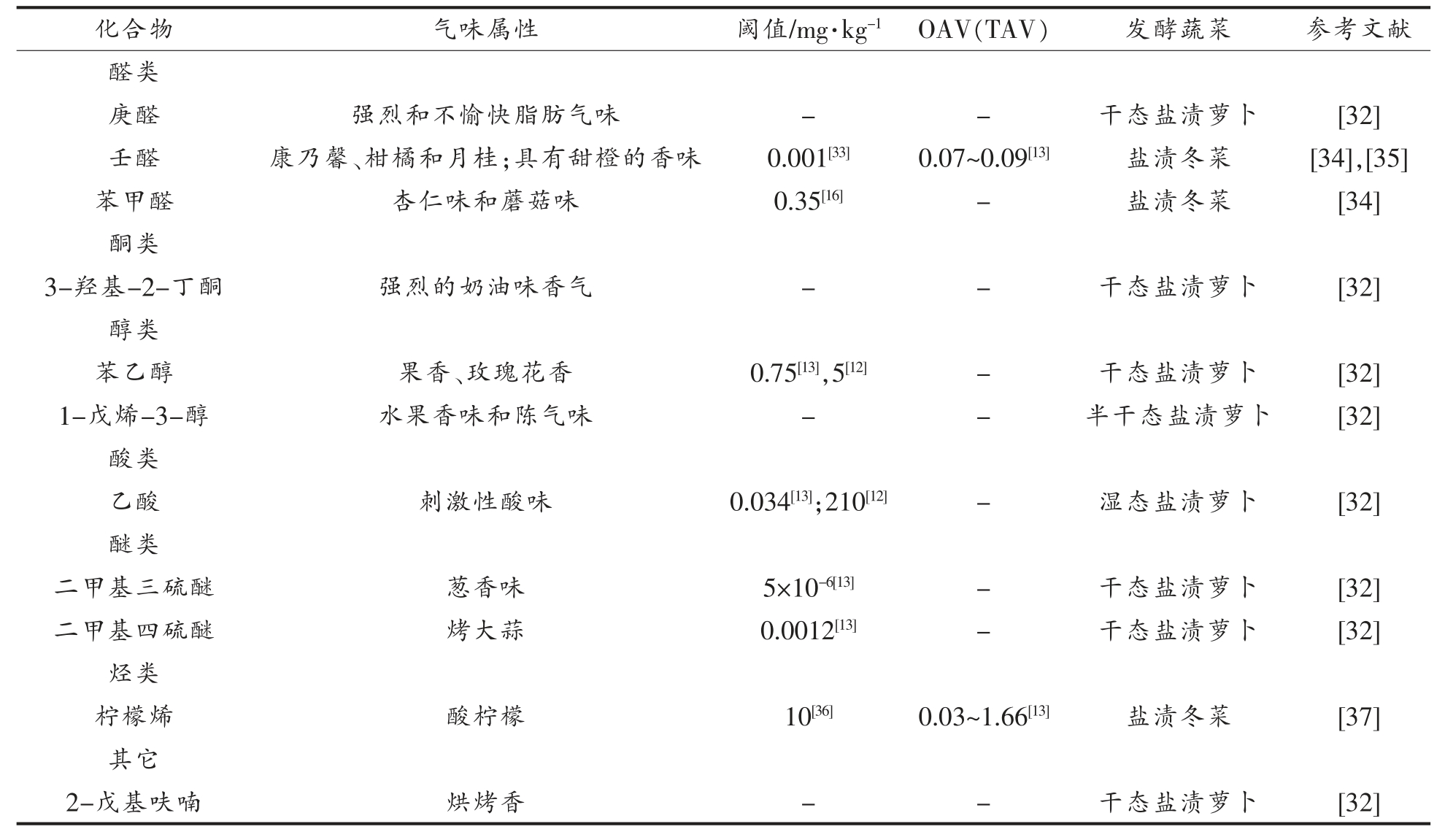

香气强度不仅与香气物质的含量有关,还与其阈值有关。通常,化合物的阈值越低越容易被感知[13]。由表2 可知,与泡菜和酱腌菜相比,盐渍菜中氨基酸、有机酸类物质较少,主要由乙酸赋予其酸味。盐渍冬菜中主要风味物质为壬醛和苯甲醛,赋予其甜橙味和杏仁味。干态盐渍萝卜中主要风味物质为二甲基三硫醚和二甲基四硫醚,赋予其葱香味、烤蒜味。湿态盐渍萝卜以乙酸为主要风味物质,赋予其刺激性酸味。

表2 盐渍菜主要风味物质

Table 2 Characteristics flavor profile of salted vegetables

1.3 酱腌菜

酱腌菜是一种经盐腌、微生物发酵和酱渍而成的蔬菜加工品。将新鲜蔬菜先用高浓度盐水腌制,通过清水冲洗或压榨等方法,降低腌制蔬菜中的食盐浓度,之后通过酱油、甜面酱、干黄酱等[38-39]进行酱制,使酱中的糖分、氨基酸、芳香物质等渗入咸菜坯中,成为味道鲜美、营养丰富、开胃增食且容易保存的酱腌菜[40]。酱腌菜的生产主要依赖于微生物发酵,发酵过程是乳酸菌主导的多种微生物的代谢过程,多种代谢产物和所需低氧环境能够抑制腐败细菌、霉菌等微生物生长,从而使酱腌菜能够保持其独特风味而不易变质。

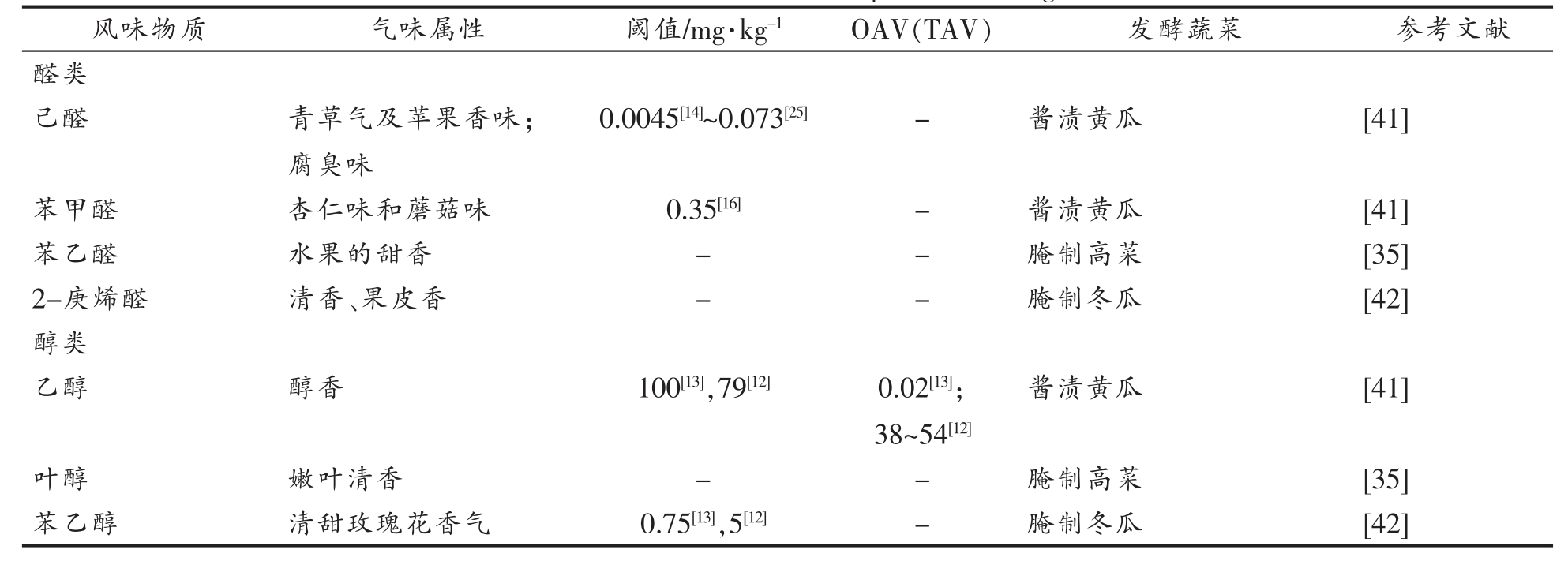

酱腌菜原料多为黄瓜、高菜、冬瓜、芫根。根据阈值,由表3 可知,酱渍黄瓜中主要风味物质为己醛、丁酸乙酯,赋予其青草香、果香;主要滋味物质为柠檬酸,赋予其丰富的酸味。腌制冬瓜中主要风味物质为乙酸乙酯,赋予其果香。此外,相比于泡菜和盐渍菜,酱腌菜中包含天冬氨酸、谷氨酸、半胱氨酸、丝氨酸、甘氨酸、组氨酸、精氨酸等多种氨基酸,其中主要氨基酸为天冬氨酸和谷氨酸,赋予酱腌菜浓郁的鲜味。

表3 酱腌菜主要风味物质

Table 3 Characteristics flavor profile of Jiangcai

(续表3)

2 发酵蔬菜中主要微生物组成

发酵蔬菜的微生物菌落种类及数量对其风味形成至关重要。以低盐榨菜为例,腌制发酵初期主要的优势菌为肠膜明串珠菌(Leuconostoc mesenteroides),随着腌制时间延长,逐渐出现植物乳杆菌(Lactobacillus plantarum)和短乳杆菌(Lactobacillus brevis),而在腌制保存后期起主导作用的微生物为植物乳杆菌和费尔斯莫尔德镇乳杆菌(Lactobacillus versmoldensis)[45-46]。特征风味的形成则由腌制初期主要的甜香、醇香,向带有更丰富的酸味转变。表4 列出不同类型中华传统发酵蔬菜的主要优势菌种。在蔬菜的起始发酵和主发酵阶段,占优势的微生物主要有植物乳杆菌、短乳杆菌、肠膜状明串珠菌、戊糖片球菌等(Pediococcus pentosaceus)[47-48]。

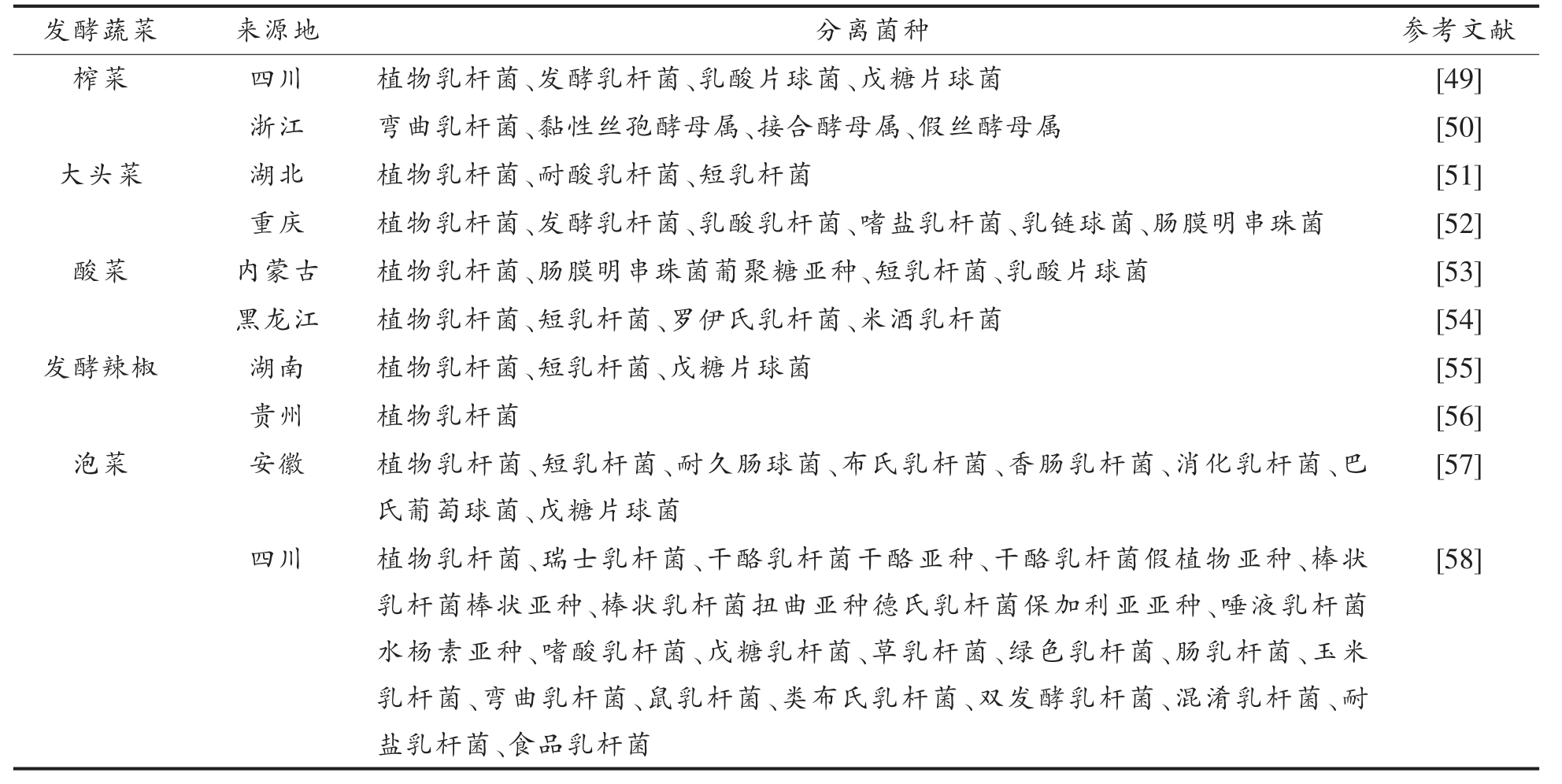

表4 中华传统发酵蔬菜主要微生物组成

Table 4 Type of microorganisms of Chinese traditional fermented vegetables

2.1 乳酸菌

乳酸菌在蔬菜发酵过程中起主导作用,参与形成食品风味的复杂代谢途径[59],产生酮类、酯类、有机酸等化合物,为发酵蔬菜提供丰富而柔和的酸味以及芳香物质。通过乳酸菌发酵的蔬菜制品,不仅可以保持原材料的鲜香脆嫩,增加乳酸发酵特有的香气,减少原料自带的刺激性气味或其它不良风味,还能产生乳酸菌素,抑制腐败菌,减少亚硝酸盐的形成,延长食品的保质期。目前,蔬菜发酵一般以乳酸发酵为主,并伴有少量的酒精发酵和微量的醋酸发酵[3]。

乳酸发酵是乳酸菌利用新鲜蔬菜中的糖类物质,代谢产生乳酸以及其它多种代谢产物的生物化学过程[60]。乳酸发酵根据生化机制不同,分为同型和异型乳酸发酵[61]。同型乳酸发酵的代谢产物90%以上都是乳酸[62],而异型乳酸发酵产生的代谢产物除50%左右的乳酸外,还生成乙醇、乙酸和CO2 等物质。发酵初期以异型乳酸发酵[62]为主,魏斯氏菌属(Weissella)、双歧杆菌属(Bifidobacterium)、明串珠菌属(Leuconostoc)和部分乳杆菌属(Lactobacillus),如短乳杆菌、发酵乳杆菌(Lactobacillus fermentum)和罗伊氏乳杆菌(Lactobacillus reuteri)均属异型发酵乳酸菌[60]。异型乳酸菌的发酵途径为磷酸解酮酶途径,产生大量CO2,使环境处于厌氧状态,同时产生少量乳酸,使环境pH 值下降,这类乳酸菌一般不耐酸[62],在发酵初期pH值下降的同时,这类乳酸菌的活动逐渐变缓。发酵中期以同型乳酸发酵为主,常见的同型乳酸菌包括片球菌属(Pediococcus)、乳球菌属(Lactococcus)、肠球菌属(Enterococcus)、链球菌属(Streptococcus)和某些乳杆菌属,例如干酪乳杆菌(Lactobacillus casei)、弯曲乳杆菌(Lactobacillus curvatus)、嗜酸乳杆菌(Lactobacillus acidophilus)和植物乳杆菌等[60],它们通过糖酵解代谢途径[60],可将80 %以上葡萄糖转化为乳酸[63],使体系迅速变酸,抑制不耐酸的杂菌生长。到发酵后期,乳酸菌的不断产酸,导致乳酸含量增加到抑制乳酸菌自身的生长,发酵慢慢减弱直至停止。

除了乳酸发酵,蔬菜发酵还伴随着酒精发酵和醋酸发酵,生成乳酸、醋酸和乙醇等物质,既对发酵蔬菜起防腐作用,又给产品带来酸味和乙醇的香气[64]。发酵后期,环境较适合酵母菌的生长发育,酵母菌在缺氧条件下进行酒精发酵生成乙醇。乙醇作为醋酸发酵的底物,在有氧条件下醋酸菌把乙醇转化为醋酸,可与醇类物质发生酯化反应生成芳香族化合物,为发酵蔬菜增添香气[24]。

2.2 酵母菌

酵母菌可以发酵糖类物质产醇,代谢多种氨基酸,分泌酯酶和脂肪酶,产生大量的芳香化合物。例如,酿酒酵母(Saccharomyces cerevisiae)代谢甲硫氨酸、亮氨酸、苯丙氨酸和缬氨酸等,通过Ehrlich 途径生产芳香醇、酯和醛等[62,65]。脂肪酸乙酯或高级醇乙酸酯通过酵母菌的酯酶活性[66]或化学酯化形成,有助于增加发酵蔬菜的风味[27]。

发酵过程中主要的酵母菌有异常汉逊酵母(Hansenula anomala)、伊萨酵母属(Issatchenkia)、毕赤酵母属(Pichia)、德巴利氏酵母属(Debaryomyces)和红酵母属(Rhodotorula)等[27]。例如,酸黄瓜在发酵时起主要作用的酵母菌依次为亚膜汉逊酵 母(Wickerhamomyces subpelliculosus)、罗斯酵母(Saccharomyces rosei)、拜耳酵母(Saccharomyces baillii)和异常汉逊酵母[67]。青菜泡菜中,汉逊德巴利氏酵母(Debaryomyces hansenii)作为风味物质形成的重要菌属,可以利用葡萄糖产生乙酸乙酯和D-阿拉伯糖,赋予泡菜更加协调的风味[68]。

发酵蔬菜是多菌共酵体系,乳酸菌和酵母菌可能发生协同、竞争等互作,影响风味形成。比如酵母菌在生长代谢过程中产生促乳酸菌生长因子丙酮酸、丙酸、琥珀酸等[69]。同时,一些乳酸菌在乳糖代谢过程中也可释放副产物半乳糖,可被乳糖阴性酵母菌利用[70]。另外,它们还可能出现竞争。从发酵蔬菜中分离获得的肠膜明串珠菌和植物乳杆菌两者生长存在竞争关系,其导致混合培养时,乳酸生成量与单独培养相比存在显著差异[71]。蔬菜发酵过程中微生物群落间的互作关系,不仅促进菌群结构相对稳定,也维持了风味物质代谢的正常时序[72]。

3 微生物诱导发酵蔬菜风味形成机制

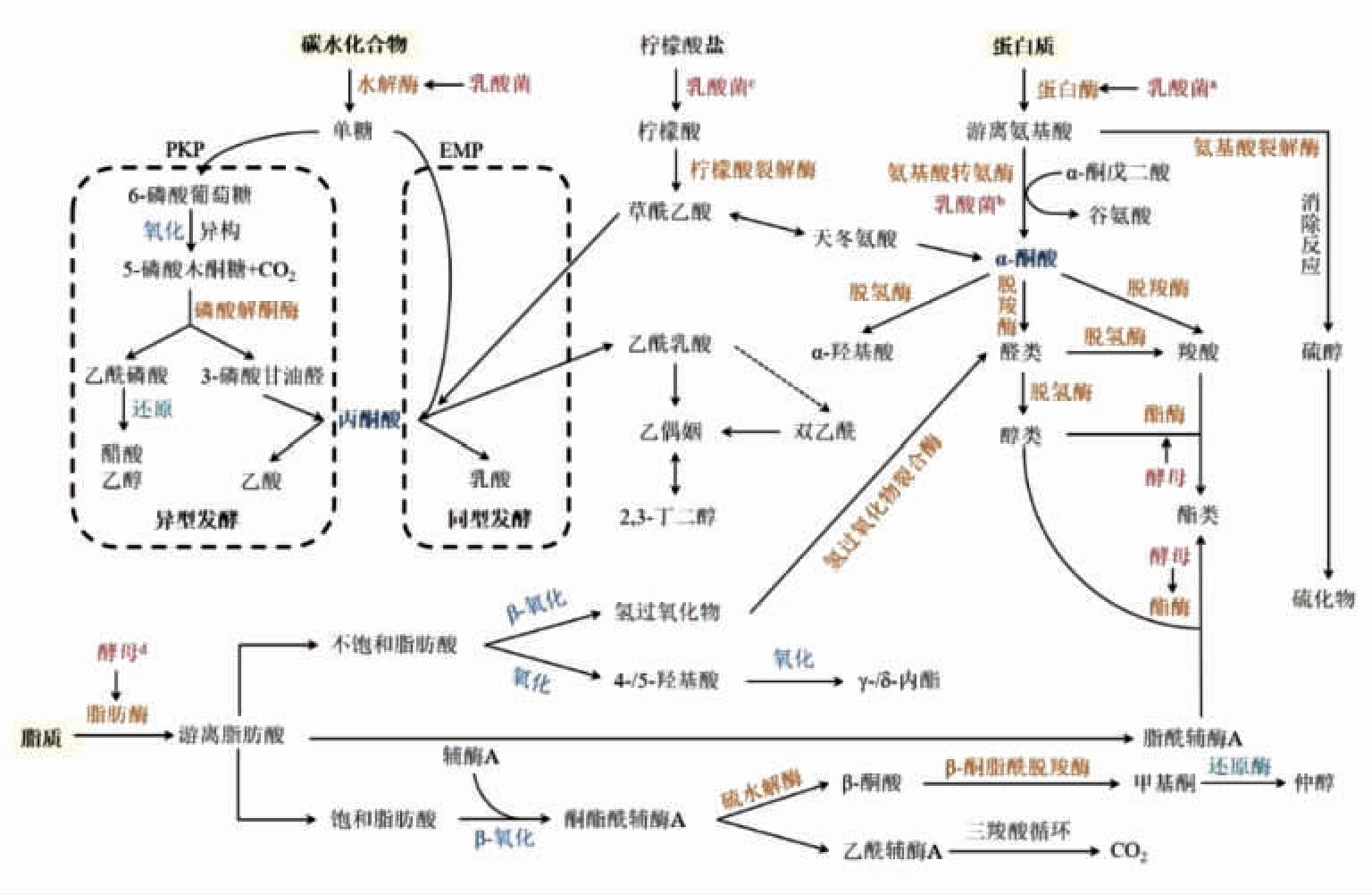

风味物质的形成多源于发酵体系复杂的微生物代谢[5]。微生物可将蔬菜基质中的碳水化合物、蛋白质分解为乳酸、乙醇、醋酸、氨基酸等物质,并进一步生成酮类、醛类、酯类等多种风味物质。发酵蔬菜微生物参与风味物质形成的主要关键代谢途径为:1)碳水化合物代谢;2)蛋白质水解和氨基酸分解代谢;3)脂肪分解和脂肪酸代谢(图2)。

图2 中华传统发酵蔬菜风味形成主要代谢途径

Fig.2 Main reaction pathways of flavor formed in Chinese traditional fermented vegetables

注:a.干酪乳杆菌、植物乳杆菌、弯曲乳杆菌、清酒乳杆菌、乳球菌等[73-74];b.清酒乳杆菌等[75];c.乳酸乳球菌、肠膜明串珠菌等[76];d.加利福尼亚拟威尔酵母、酿酒酵母等[77]。

3.1 碳水化合物代谢

发酵蔬菜中的糖类物质主要有果糖、蔗糖、葡萄糖和甘露糖等。这些碳水化合物可以通过同型发酵和异型发酵产生醇类、有机酸类物质[13](图2)。

异型乳酸菌的发酵途径为磷酸解酮酶途径,即葡萄糖先被分解为6-磷酸葡萄糖,这是形成丙酮酸的重要中间体。6-磷酸葡萄糖经氧化和差向异构得到5-磷酸木酮糖,并释放出CO2,再经磷酸解酮酶作用,转变成乙酰磷酸和3-磷酸甘油醛。乙酰磷酸进一步还原生成醋酸和乙醇,同时释放磷酸。而3-磷酸甘油醛通过丙酮酸还原成乳酸[60]。对于同型乳酸菌发酵,糖类物质通过糖酵解途径产生丙酮酸,丙酮酸随后被还原为乳酸,作为唯一产物[73]。

柠檬酸盐存在于发酵蔬菜中,通过利用柠檬酸盐的乳酸菌,如乳酸乳球菌(Lactococcus lactis)和肠膜明串珠菌与糖类共同代谢[76]。柠檬酸可以通过柠檬酸裂解酶转化为草酰乙酸和乙酸盐。草酰乙酸在草酰乙酸脱羧酶催化作用下产生二氧化碳和丙酮酸。随后,丙酮酸的消散产生挥发性化合物,如2,3-丁二醇、双乙酰和乙偶姻,赋予发酵蔬菜令人愉悦的醇香、奶油香[78-79]。

3.2 蛋白质水解和氨基酸代谢

蛋白质水解是食品发酵和成熟期间产生风味物质的主要生化反应之一[80]。蛋白质可被乳酸菌,如干酪乳杆菌、植物乳杆菌、弯曲乳杆菌和清酒乳杆菌(Lactobacillus sakei)水解为肽和氨基酸[73]。大的疏水肽与苦味有关,氨基酸也可赋予发酵蔬菜酸味(酪氨酸、苯丙氨酸和丙氨酸)、苦味(组氨酸、亮氨酸、精氨酸、苯丙氨酸、异亮氨酸、赖氨酸和缬氨酸)、甜味(丙氨酸、甘氨酸、苏氨酸、丝氨酸、脯氨酸和羟脯氨酸)和鲜味/咸味(天冬氨酸和谷氨酸)[81-82]。

此外,游离氨基酸可作为后续风味形成的底物。游离氨基酸向挥发性化合物转化有两条途径:一是氨基酸裂解酶催化的消除反应,主要是蛋氨酸和苏氨酸通过消除反应生成含硫化合物,碳硫裂解酶导致硫醇的释放,硫醇可以转化为硫化合物(大蒜、卷心菜和煮土豆的气味)[83-84];二是由氨基酸转氨酶引发的转氨反应[85]。转氨途径由转氨酶启动,转氨酶将α-酮戊二酸转化为谷氨酸,同时将氨基酸转化为α-酮酸风味前体。生成的α-酮酸经各种酶促反应,包括由羟基酸脱氢酶催化的还原反应生成α-羟基酸和脱羧反应生成醛。醛可以被醇脱氢酶进一步还原为醇,并被醛脱氢酶氧化为有机酸,或经过氧化脱羧作用形成酰基辅酶A 和羧酸[86]。

3.3 脂肪分解和脂肪酸代谢

脂质水解释放出的游离脂肪酸,是发酵食品重要的香气化合物[87]。这些游离脂肪酸可由加利福尼亚拟威尔酵母(Williopsis californica)[88]、酿酒酵母[88]、乳球菌属和乳杆菌属降解脂肪产生[89]。例如,一种革兰氏阳性变形菌产生脂肪酶,将芳樟醇和甲酸进行酯化生成芳樟醇甲酯,赋予四川泡菜果味和玫瑰香味[18]。

游离脂肪酸,包括饱和脂肪酸和不饱和脂肪酸,作为分解代谢反应的前体,通过脂质氧化产生某些挥发性化合物,如烷烃、甲基酮、仲醇和内酯[90-91]。饱和脂肪酸通过β-氧化使β-酮酸脱羧产生奇数碳甲基酮[92]。甲基酮可被还原酶还原成相应的仲醇[93]。不饱和脂肪酸的氧化有两条途径:一是在自由基存在的情况下,不饱和脂肪酸通过β氧化形成氢过氧化物;二是可以导致4-/5-羟基酸的形成,这些酸被转化为γ-/δ-内酯,提供浓郁的水果风味[94]。

4 总结与展望

我国传统发酵蔬菜类别繁多且具有明显的风味特征,目前关于其的研究主要集中在微生物群落多样性与风味组分相关性分析,而相应的验证试验不全面。在生产过程中,多菌共酵体系下乳酸菌和酵母菌如何协同、竞争和互作而产生风味物质的机制还有待研究。

基于此,今后可从以下3 个方面展开深入研究:1)我国幅员辽阔,各地生活差异显著,造就了微生物多样、风味多样的中华传统发酵蔬菜,未来应进一步挖掘其中的特征性风味物质,开展精准筛选、组学鉴定、定向驯化及菌种资源保护等,为中华传统发酵蔬菜的风味提升和新产品创制提供有力保障;2)随着分子生物学和生物信息学等学科的发展,应充分利用宏基因组学、转录组学、代谢组学、蛋白质组学等组学技术,开展微生物多样性挖掘等工作,实现对微生物代谢通路的预测,并通过反向验证手段,确定微生物诱导产生特征性风味物质的作用机制;3)基于中华传统发酵蔬菜工艺,在保证原有特征性风味基础上,开展标准化、数字化、智能化直投式发酵新工艺及装备的突破,以促进传统发酵蔬菜现代工业化生产。

[1] LIANG J J,LI D,SHI R,et al.Effects of microbial community succession on volatile profiles and biogenic amine during sufu fermentation[J].LWT -Food Science and Technology,2019,114:108379.

[2] 宣丽,刘长江,史铁嘉.酸白菜发酵的机理研究[J].农业科技与装备,2010(7):18-19.

XUAN L,LIU C J,SHI T J.Study on mechanism of pickling Chinese cabbage[J].Agricultural Science&Technology and Equipment,2010(7):18-19.

[3] 吴华昌,张伟娜,邓静,等.腌菜风味物质研究进展[J].中国调味品,2010,35(11):26-29.

WU H C,ZHANG W N,DENG J,et al.Advances of study on flavor of pickled vegetable[J].China Condiment,2010,35(11):26-29.

[4] 叶陵.植物乳杆菌W-4 的分离鉴定及其发酵剁辣椒研究[D].长沙:湖南农业大学,2017.

YE L.Isolation,identification of Lactobacillus plantarum W-4 and its application in chopped pepper[D].Changsha:Hunan Agricultural University,2017.

[5] 解春芝.基于氨基酸代谢的腐乳酱风味促熟及机理研究[D].贵阳:贵州大学,2019.

XIE C Z.Study on the flavor and mechanism of fermented bean curd sauce based on amino acid metabolism[D].Guiyang:Guizhou University,2019.

[6] WANG Z,XU Z,SUN L,et al.Dynamics of microbial communities,texture and flavor in suan zuo yu during fermentation[J].Food Chemistry,2020,332:127364.

[7] LUO W,CHEN M,CHEN A,et al.Isolation of lactic acid bacteria from pao cai,a Chinese traditional fermented vegetable,with inhibitory activity against Salmonella associated with fresh-cut apple,using a modelling study[J].Journal of Applied Microbiology,2015,118(4):998-1006.

[8] 陈功.试论中国泡菜历史与发展[J].食品与发酵科技,2010,46(3):1-5.

CHEN G.The history and development of Chinese pickles[J].Food and Fermentation Science &Technology,2010,46(3):1-5.

[9] XIAO Y,HUANG T,XU Y,et al.Metatranscriptomics reveals the gene functions and metabolic properties of the major microbial community during Chinese Sichuan Paocai fermentation[J].Food Microbiology,2020,98:103573.

[10] 熊家卉,李璨.泡菜生产过程主要发酵微生物的研究进展[J].山东化工,2021,50(4):87-88.

XIONG J H,LI C.Research progress of main fer mentative microorganisms in kimchi production[J].Shandong Chemical Industry,2021,50(4):87-88.

[11] 汪冬冬,鲍永碧,管锐,等.温度对甘蓝泡菜发酵过程中风味的影响[J].食品与发酵工业,2021,47(2):233-240.

WANG D D,BAO Y B,GUAN R,et al.Effect of temperature on the flavor of cabbage Paocai during fermentation[J].Food and Fermentation Industries,2021,47(2):233-240.

[12] ZHANG Q X,ZHANG F,GONG C J,et al.Physicochemical,microbial,and aroma characteristics of Chinese pickled red peppers(Capsicum annuum)with and without biofilm[J].Royal Society of Chemistry Advances,2020,10(11):6609-6617.

[13] 云琳.不同发酵方式的萝卜泡菜风味特征解析及发酵剂菌种的筛选[D].无锡:江南大学,2020.

YUN L.Analysis of the flavor characteristics of radish pickles with different fermentation methods and selection of the starter cultures[D].Wuxi:Jiangnan University,2020.

[14] 李多佳,贠建民,姚博,等.不同加热处理对浆水挥发性成分变化的影响[J].食品与发酵工业,2017,43(2):115-121.

LI D J,YUN J M,YAO B,et al.Effect of different heat treatments on the volatile flavor components of Jiangshui[J].Food and Fermentation Industries,2017,43(2):115-121.

[15] 沈菲儿.乳酸菌发酵对莲藕泡菜质构和风味影响的研究[D].扬州:扬州大学,2016.

SHEN F E.Effects of lactic acid bacteria fermentation on texture and flavor of lotus root pickle[D].Yangzhou:Yangzhou University,2016.

[16] SANSONE-LAND A,TAKEOKA G R,SHOEMAKER C F.Volatile constituents of commercial imported and domestic black-ripe table olives(Olea europaea)[J].Food Chemistry,2014,149:285-295.

[17] 汪甚彤,王丽,孙敏,等.芋头叶柄泡菜泡制工艺优化及其香气物质研究[J].湖北农业科学,2021,60(2):137-143,179.

WANG S T,WANG L,SUN M,et al.Optimization of pickling process and study on aroma substances of taro petiole kimchi[J].Hubei Agricultural Sciences,2021,60(2):137-143,179.

[18] 肖阳生.四川泡菜功能微生物代谢调控机理的研究[D].南昌:南昌大学,2020.

XIAO Y S.Study on the mechanism of functional microorganisms in metabolism regulation during Sichuan paocai fermentation[D].Nanchang:Nanchang University,2020.

[19] DIEZ-SIMON C,EOCHELSHEIM C,MUMM R,et al.Chemical and sensory characteristics of soy sauce:A review[J].Journal of Agricultural and Food Chemistry,2020,68(42):11612-11630.

[20] 李晓天.果蔬发酵专用乳酸菌的筛选及其在胡萝卜发酵中的应用研究[D].济南:齐鲁工业大学,2019.

LI X T.Studies on the isolation of lactic acid bacteria specific for vegetable and application in carrot fermentation[D].Jinan:Qilu University of Technology,2019.

[21] 王媛,祝霞,杨学山,等.混菌发酵对美乐低醇桃红葡萄酒香气的影响[J].核农学报,2018,32(11):2195-2207.

WANG Y,ZHU X,YANG X S,et al.Effects of co-fermentation on volatile compounds of Merlot low alcohol rose wine[J].Journal of Nuclear Agricultural Sciences,2018,32(11):2195-2207.

[22] 郑文迪,关倩倩,刘长根,等.基于GC-MS 法对比广西地区酸菜和酸笋风味的差异[J].食品与发酵工业,2020,46(4):253-257.

ZHENG W D,GUAN Q Q,LIU C G,et al.Comparison of flavors of Suancai and Suansun in Guangxi based on GC-MS[J].Food and Fermentation Industries,2020,46(4):253-257.

[23] 李志斌,李净.浓香型白酒中辛酸乙酯含量及其风味贡献分析[J].酿酒科技,2013,34(4):65-67.

LI Z B,LI J.Analysis of the content of ethyl caprylate in Nong -flavor liquor and its flavoring contributions[J].Liquor-Making Science &Technology,2013,34(4):65-67.

[24] 王鑫宇.天然发酵酸菜中乳酸菌的分离及发酵特性的评价[D].长春:吉林大学,2019.

WANG X Y.Isolation of lactic acid bacteria from naturally fermented sauerkraut and evaluation of fermentation characteristics[D].Changchun:Jilin University,2019.

[25] XU X X,WU B B,ZHAO W T,et al.Correlation between autochthonous microbial communities and key odorants during the fermentation of red pepper(Capsicum annuum L.)[J].Food Microbiology,2020,91:103510.

[26] 周相玲,胡安胜,王彬,等.人工接种泡菜与自然发酵泡菜风味物质的对比分析[J].中国酿造,2011,30(1):159-160.

ZHOU X L,HU A S,WANG B,et al.Comparison analysis of flavor compounds in pickles produced by inoculated fermentation and natural fermentation[J].China Brewing,2011,30(1):159-160.

[27] 屠梦婷.发酵黄瓜中酵母的分离鉴定及其对发酵黄瓜风味的影响[D].杭州:浙江农林大学,2019.

TU M T.Isolation and identification of yeasts in fermented cucumber and its effects on the flavor of fermented cucumber[D].Hangzhou:Zhejiang A &F University,2019.

[28] CHA Y J,KIM H,CADWALLADER K R.Aromaactive compounds in kimchi during fermentation[J].Journal of Agricultural and Food Chemistry,1998,46(5):1944-1953.

[29] XU X X,WU B B,ZHAO W T,et al.Shifts in autochthonous microbial diversity and volatile metabolites during the fermentation of chili pepper(Capsicum frutescens L.)[J].Food Chemistry,2020,335:127512.

[30] 张鹰,白卫东,刘晓艳,等.低盐腌菜保藏技术研究进展[J].现代食品科技,2013,29(4):921-924.

ZHANG Y,BAI W D,LIU X Y,et al.Advances of the preservation technologies of low-salt pickled vegetables[J].Modern Food Science and Technology,2013,29(4):921-924.

[31] 尹礼国,高煜然,李华兰,等.盐渍萝卜的细菌菌群结构DGGE 分析[J].中国调味品,2015,40(6):102-105.

YIN L G,GAO Y R,LI H L,et al.DGGE analysis of bacterial community structures of salted Raphanus sativus L.[J].China Condiment,2015,40(6):102-105.

[32] 汪冬冬,唐垚,陈功,等.不同发酵方式盐渍萝卜挥发性成分动态分析[J].食品科学,2020,41(6):146-154.

WANG D D,TANG Y,CHEN G,et al.Dynamic analysis of volatile components of salted radish during different fermentation processes[J].Food Science,2020,41(6):146-154.

[33] PAN X,WU J H,ZHANG W T,et al.Effects of sugar matrices on the release of key aroma compounds in fresh and high hydrostatic pressure processed Tainong mango juices[J].Food Chemistry,2020,338:128117.

[34] XIAO Y Q,LIU Y N,CHEN C G,et al.Effect of Lactobacillus plantarum and Staphylococcus xylosus on flavour development and bacterial communities in Chinese dry fermented sausages[J].Food Research International,2020,135:109247.

[35] 陈秋佳.华容芥菜和高菜主要营养成分分析及高菜乳酸发酵过程中营养成分变化规律研究[D].长沙:湖南农业大学,2019.

CHEN Q J.Analysis of main nutrients of Huarong mustard and Brassica juncea var.integlifolia and study on the variation of nutritional components in lactic acid fermentation in Brassica juncea var.integlifolia[D].Changsha:Hunan Agricultural University,2019.

[36] MANRÍQUEZ D A,MUÑOZ-ROBREDO P,GUDENSCHWAGER O,et al.Development of flavorrelated metabolites in cherimoya(Annona cherimola Mill.)fruit and their relationship with ripening physiology[J].Postharvest Biology and Technology,2014,94:58-65.

[37] MORETTI V M,MADONIA G,DIAFERIA C,et al.Chemical and microbiological parameters and sensory attributes of a typical Sicilian salami ripened in different conditions[J].Meat Science,2004,66(4):845-854.

[38] PARK E J,CHANG H W,KIM K H,et al.Application of quantitative real-time PCR for enumeration of total bacterial,archaeal,and yeast populations in kimchi[J].The Journal of Microbiology,2009,47(6):682-685.

[39] 冯春梅,李建强,黎新荣,等.油渍食用菌酱菜工艺技术研究[J].食品工业科技,2007(12):161-162.

FENG C M,LI J Q,LI X R,et al.Study on technology of Jiangcai with edible fungus[J].Science and Technology of Food Industry,2007(12):161-162.

[40] 傅亮,鲍玲玲,吴炳鸿,等.豆类多肽对酱菜发酵中亚硝酸盐降解影响的研究[J].中国调味品,2012,37(11):32-35.

FU L,BAO L L,WU B H,et al.The beans peptide degradate nitrite content in fermented pickles[J].China Condiment,2012,37(11):32-35.

[41] 李晓.低盐腌渍黄瓜质构与风味变化的研究[D].泰安:山东农业大学,2019.

LI X.Study on the texture and flavor of low-salted pickled cucumber[D].Tai'an:Shandong Agricultural University,2019.

[42] 张庆峰,吴祖芳,张鑫,等.复合乳酸菌接种发酵对浙东腌冬瓜发酵品质的影响[J].核农学报,2017,31(3):500-507.

ZHANG Q F,WU Z F,ZHANG X,et al.Effects of complex starter cultures on the fermentation quality of pickled wax gourd of eastern Zhejiang [J].Journal of Nuclear Agricultural Sciences,2017,31(3):500-507.

[43] 盛怀宇,信思悦,王振帅,等.两种脱水处理方式对芫根腌制品品质的影响[J].食品与发酵工业,2019,45(12):152-159.

SHENG H Y,XIN S Y,WANG Z S,et al.Effects of dehydration method on the quality of pickled turnips [J].Food and Fermentation Industries,2019,45(12):152-159.

[44] LI D,DUAN F,TIAN Q,et al.Physiochemical,microbiological and flavor characteristics of traditional Chinese fermented food Kaili Red Sour Soup[J].LWT -Food Science and Technology,2021,142:110933.

[45] 张锐,吴祖芳,沈锡权,等.榨菜低盐腌制过程的微生物群落结构与动态分析[J].中国食品学报,2011,11(3):175-180.

ZHANG R,WU Z F,SHEN X Q,et al.Microbial community structure and its dynamic analysis during the processing of low-salinity pickled mustard tuber[J].Journal of Chinese Institute of Food Science and Technology,2011,11(3):175-180.

[46] 翁佩芳,吴祖芳,龚业,等.SSCP 方法的条件优化与榨菜低盐腌制微生物多样性分析[J].食品与生物技术学报,2011,30(2):261-266.

WENG P F,WU Z F,GONG Y,et al.Optimization of SSCP condition and diversity of microbial community in pickled mustard tuber with low salinity[J].Journal of Food Science and Biotechnology,2011,30(2):261-266.

[47] 胡晓清,潘露,王汝毅.发酵蔬菜中乳酸菌的功能性与安全性研究进展[J].现代食品科技,2012,28(11):1606-1611.

HU X Q,PAN L,WANG R Y.Advances in the functionality and safety of lactic acid bacteria from fermented vegetable[J].Modern Food Science and Technology,2012,28(11):1606-1611.

[48] XIONG T,SONG S,HUANG X,et al.Screening and identification of functional Lactobacillus specific for vegetable fermentation[J].Journal of Food Science,2013,78(1):M84-M89.

[49] 杨珺,吴永娴,曾凡坤.四川榨菜后熟时期微生物区系的初探[J].食品科学,1999,20(12):50-51.

YANG J,WU Y X,ZENG F K.Preliminary study on microflora of Sichuan mustard during post-ripening period[J].Food Science,1999,20(12):50-51.

[50] 荆雪娇.传统发酵蔬菜微生物群落结构分析[D].太原:山西大学,2016.

JING X J.Microbial community structure analysis of traditional fermented vegetables[D].Taiyuan:Shanxi University,2016.

[51] 杨雪,陶兴无,高冰,等.发酵大头菜中乳酸菌的分离鉴定及生产初试[J].中国酿造,2008,27(9):31-33.

YANG X,TAO X W,GAO B,et al.Isolation and identification of lactic acid bacteria from fermented kohlrabi followed by the application in preliminary production[J].China Brewing,2008,27(9):31-33.

[52] 吴希茜.自然发酵腌制大头菜发酵过程中细菌的分离鉴定[J].山东食品发酵,2011,41(4):11-14.

WU X Q.Isolation and identification of bacteria from fermented kohlrabi in natural fermentation process[J].Shandong Food Ferment,2011,41(4):11-14.

[53] 赵岩.赤峰地区酸菜中乳酸菌的筛选与初步鉴定[J].中国酿造,2013,32(5):35-37.

ZHAO Y.Screening and preliminary identification of lactic acid bacteria from traditional fermented sauerkraut in Chifeng[J].China Brewing,2013,32(5):35-37.

[54] 张鲁冀,孟祥晨.自然发酵东北酸菜中乳杆菌的分离与鉴定[J].东北农业大 学学报,2010,41(11):125-131.

ZHANG L J,MENG X C.Isolation and indentification of Lactobacilli from natural fermented Suancai[J].Journal of Northeast Agricultural University,2010,41(11):125-131.

[55] 钟燕青.自然发酵辣椒中乳酸菌分离筛选及香气成分分析[D].长沙:湖南农业大学,2012.

ZHONG Y Q.The isolation of Lactobacillus and the analysis of aroma components in natural fermented pepper[D].Changsha:Hunan Agricultural University,2012.

[56] 王修俊,王丽芳,郑君花,等.贵州发酵辣椒中优良乳酸菌的分离鉴定及生长特性研究[J].食品科技,2014,39(10):17-21.

WANG X J,WANG L F,ZHENG J H,et al.Study on isolation,identification and growth characteristics of excellent lactic acid bacteria from fermentated pepper of Guizhou[J].Food Science and Technology,2014,39(10):17-21.

[57] 盛海圆.传统泡菜中乳酸菌的分离鉴定及其多样性分析[D].合肥:安徽农业大学,2010.

SHENG H Y.Identification and the biodiversity of lactic acid bacteria from the traditional fermented vegetable[D].Hefei:Anhui Agricultural University,2010.

[58] 周光燕.四川地区自然发酵泡菜中乳酸菌的生物特性研究[D].雅安:四川农业大学,2006.

ZHOU G Y.Investigation of the biological characteristics of lactic acid bacteria isolated from traditional fermented pickle samples in the Sichuan Province[D].Ya'an:Sichuan Agricultural University,2006.

[59] FILANNINO P,CAGNO R D,GOBBETTI M.Metabolic and functional paths of lactic acid bacteria in plant foods:get out of the labyrinth[J].Current Opinion in Biotechnology,2018,49:64-72.

[60] 张菊华,单杨,李高阳.乳酸菌发酵蔬菜汁的呈味作用[J].湖南农业科学,2004,34(1):67-70.

ZHANG J H,SHAN Y,LI G Y.Discussion on flavor developing effects of vegetable juice fermented by lactic acid bacteria[J].Hunan Agricultural Sciences,2004,34(1):67-70.

[61] 张会生.直投式乳酸菌发酵泡菜技术研究[D].南昌:南昌大学,2019.

HANG H S.Optimization of technology of direct vat set pickles fermented by lactic acid bacteria [D].Nanchang:Nanchang University,2019.

[62] 王金菊,崔宝宁,张治洲.泡菜风味形成的原理[J].食品研究与开发,2008,29(12):163-166.

WANG J J,CUI B N,ZHANG Z Z.Flavor generation mechanism of pickle[J].Food Research and Development,2008,29(12):163-166.

[63] 刘璞,吴祖芳,翁佩芳.榨菜腌制品风味研究进展[J].食品研究与开发,2006,27(1):158-161.

LIU P,WU Z F,WENG P F.Advances of study on flavor of pickled mustard tuber[J].Food Research and Development,2006,27(1):158-161.

[64] 周晓媛,夏延斌.蔬菜腌制品的风味研究进展[J].食品与发酵工业,2004,30(4):104-108.

ZHOU X Y,XIA Y B.Advances of study on flavor of salted vegetable[J].Food and Fermentation Industries,2004,30(4):104-108.

[65] HAZELWOOD L A,DARAN J M,MARIS A,et al.The Ehrlich pathway for fusel alcohol production:a century of research on Saccharomyces cerevisiae metabolism[J].Applied and Environmental Microbiology,2008,74(12):2259-2266.

[66] NYKÄNEN L.Formation and occurrence of flavor compounds in wine and distilled alcoholic beverages[J].American Journal of Enology and Viticulture,1986,37(1):84-86.

[67] 张鹏.四川泡菜中酵母菌的分离筛选及其应用研究[D].哈尔滨:东北农业大学,2007.

ZHANG P.Study in isolation and selection of yeast from Sichuan pickle and its application[D].Harbin:Northeast Agricultural University,2007.

[68] WU R N,YU M L,LIU X Y,et al.Changes in flavour and microbial diversity during natural fermentation of Suan-cai,a traditional food made in Northeast China[J].International Journal of Food Microbiology,2015,211:23-31.

[69] LEROI F,PIDOUX M.Characterization of interactions between Lactobacillus hilgardii and Saccharomyces florentinus isolated from sugary kefir grains[J].Journal of Applied Microbiology,2010,74(1):54-60.

[70] GADAGA T H,MUTUKUMIRA A N,NARVHUS J A.The growth and interaction of yeasts and lactic acid bacteria isolated from Zimbabwean naturally fermented milk in UHT milk[J].International Journal of Food Microbiology,2001,68(1/2):21-32.

[71] XIONG T,PENG F,LIU Y,et al.Fermentation of Chinese sauerkraut in pure culture and binary coculture with Leuconostoc mesenteroides and Lactobacillus plantarum[J].LWT -Food Science and Technology,2014,59(2):713-717.

[72] 黄玉立,赵楠,黄庆,等.发酵蔬菜风味物质形成机制及影响因素研究进展[J].食品与发酵工业,2021,47(24):279-285.

HUANG Y L,ZHAO N,HUANG Q,et al.Research progress in formation mechanism and influencing factors of flavor compounds in fermented vegetables [J].Food and Fermentation Industries,2021,47(24):279-285.

[73] BINTSIS T.Lactic acid bacteria as starter cultures:An update in their metabolism and genetics[J].AIMS Microbiology,2018,4(4):665.

[74] NÁJERA-DOMÍNGUEZ C,GUTIÉRREZ-MÉNDEZ N.Autolytic and proteolytic properties of strains of Lactococcus lactis isolated from different vegetables,raw-milk cheeses and commercial starter cultures[J].Food and Nutrition Sciences,2013,4(11A):21-26.

[75] GUTSCHE K A,TRAN T,VOGEL R F.Production of volatile compounds by Lactobacillus sakei from branched chain α-keto acids[J].Food Microbiology,2012,29(2):224-228.

[76] HUGENHOLTZ J.Citrate metabolism in lactic acid bacteria[J].FEMS Microbiology Reviews,1993,12(1-3):165-178.

[77] CIAFARDINI G,ZULLO B A,CIOCCIA G,et al.Lipolytic activity of Williopsis californica and Saccharomyces cerevisiae in extra virgin olive oil[J].International Journal of Food Microbiology,2006,107(1):27-32.

[78] ERKUS O,JAGER V D,SPUS M,et al.Multifactorial diversity sustains microbial community stability[J].ISME Journal,2013,7(11):2126-2136.

[79] COLLINS E B.Biosynthesis of flavor compounds by microorganisms[J].Journal of Dairy Science,1972,55(7):1022-1028.

[80] JANE V,DIAS F S.Protective,technological,and functional properties of select autochthonous lactic acid bacteria from goat dairy products[J].Current Opinion in Food Science,2017,13:1-9.

[81] RAMALINGAM V,SONG Z,HWANG I.The potential role of secondary metabolites in modulating the flavor and taste of the meat[J].Food Research International,2019,122:174-182.

[82] BACHMANO A A,BOSAK N P,GLENDINNING J I,et al.Genetics of amino acid taste and appetite[J].Advances in Nutrition,2016,7(4):806S-822S.

[83] LIU M J,NAUTA A,FRANCKE C,et al.Comparative genomics of enzymes in flavor -forming pathways from amino acids in lactic acid bacteria[J].Applied and Environmental Microbiology,2008,74(15):4590-4600.

[84] MCAULIFFE O,KILCAWLEY K,STEFANOVIC E.Symposium review:Genomic investigations of flavor formation by dairy microbiota[J].Journal of Dairy Science,2019,102(1):909-922.

[85] YVON M,RIJNEN L.Cheese flavour formation by amino acid catabolism[J].International Dairy Journal,2001,11(4-7):185-201.

[86] HU Y Y,ZHANG L,WEN R X,et al.Role of lactic acid bacteria in flavor development in traditional Chinese fermented foods:A review [J/OL].Critical Reviews in Food Science and Nutrition,(2020)[2021-07-26].https://xueshu.baidu.com/usercenter/paper/show?paperid=10230mb0fu5400j0gg2k0cw 0aj477247.

[87] ANJUM M M,SALIM U-R,MUHAMMAD A F,et al.Cheddar cheese ripening and flavor characterization:A review[J].Critical Reviews in Food Science and Nutrition,2014,54(10):1309-1321.

[88] HAN B Z,ROMBOUTS F M,NOUT M J R.A Chinese fermented soybean food[J].International Journal of Food Microbiology,2001,65(1/2):1-10.

[89] KAMALY K M,MARTH E H.Enzyme activities of Lactic streptococci and their role in maturation of cheese:A review [J].Journal of Dairy Science,1989,72(8):1945-1966.

[90] SMIT G,SMIT B A,ENGELS W J M.Flavour formation by lactic acid bacteria and biochemical flavour profiling of cheese products[J].FEMS Microbiology Reviews,2005,29(3):591-610.

[91] COLLINS Y F,MCSWEENEY P L H,WILKINSON M G.Lipolysis and free fatty acid catabolism in cheese:A review of current knowledge[J].International Dairy Journal,2003,13(11):841-866.

[92] CHENG H.Volatile flavor compounds in yogurt:A review[J].Critical Reviews in Food Science and Nutrition,2010,50(10):938-950.

[93] MOLIMARD P,SPINNLER H E.Review:Compounds involved in the flavor of surface mold -ripened cheeses:Origins and properties[J].Journal of Dairy Science,1996,79(2):169-184.

[94] WU J R,TIAN T,LIU Y M,et al.The dynamic changes of chemical components and microbiota during the natural fermentation process in Dajiang,a Chinese popular traditional fermented condiment[J].Food Research International,2018,112:457-467.