超高压处理对复合果汁微生物和品质的影响

作者:

作者单位:

作者简介:

通讯作者:

中图分类号:

基金项目:

“十三五”国家重点研发计划项目(2016YFD0400700,2016YFD0400704)

Effects of High Hydrostatic Pressure Treatment on Microorganism and Quality of Composite Juice

Author:

Affiliation:

Fund Project:

引用本文

高婧昕;刘旭;丁皓玥;廖小军;王永涛.超高压处理对复合果汁微生物和品质的影响[J].中国食品学报,2020,20(9):118-130

复制分享

文章指标

- 点击次数:

- 下载次数:

- HTML阅读次数:

历史

- 收稿日期:

- 最后修改日期:

- 录用日期:

- 在线发布日期: 2020-10-13

- 出版日期:

文章二维码

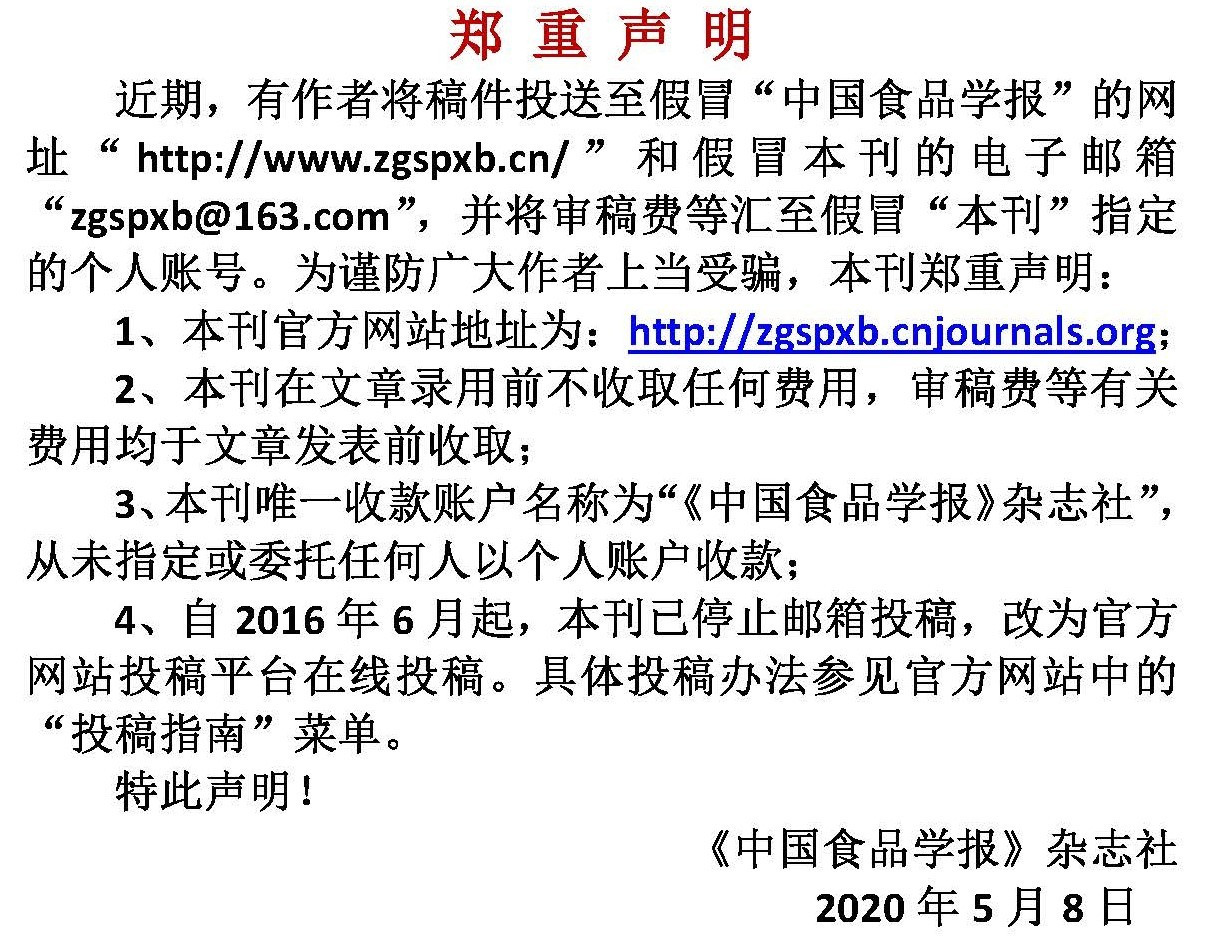

版权所有 :《中国食品学报》杂志社 京ICP备09084417号-4

地址 :北京市海淀区阜成路北三街8号9层 邮政编码 :100048

电话 :010-65223596 65265375 电子邮箱 :chinaspxb@vip.163.com

技术支持:北京勤云科技发展有限公司

地址 :北京市海淀区阜成路北三街8号9层 邮政编码 :100048

电话 :010-65223596 65265375 电子邮箱 :chinaspxb@vip.163.com

技术支持:北京勤云科技发展有限公司