4种凝结型亲水胶体对酸性低温杀菌魔芋凝胶品质的改善作用

作者:

作者单位:

(江西农业大学食品科学与工程学院 南昌 330045)

作者简介:

通讯作者:

中图分类号:

基金项目:

江西省现代农业产业技术体系建设专项(JXARS-19-4)

Effect of Four Kinds of Agglutinating Hydrocolloids on the Quality of Konjac Glucomannan Gels by Acidic Low-temperature Sterilization

Author:

Affiliation:

(College of Food Science and Engineering, Jiangxi Agricultural University, Nanchang 330045)

Fund Project:

引用本文

胡帅,刘沙,冯娅萍,张勉羚,牛丽亚,肖建辉.4种凝结型亲水胶体对酸性低温杀菌魔芋凝胶品质的改善作用[J].中国食品学报,2024,24(12):246-255

复制分享

文章指标

- 点击次数:

- 下载次数:

- HTML阅读次数:

历史

- 收稿日期:2023-12-01

- 最后修改日期:

- 录用日期:

- 在线发布日期: 2025-01-23

- 出版日期:

文章二维码

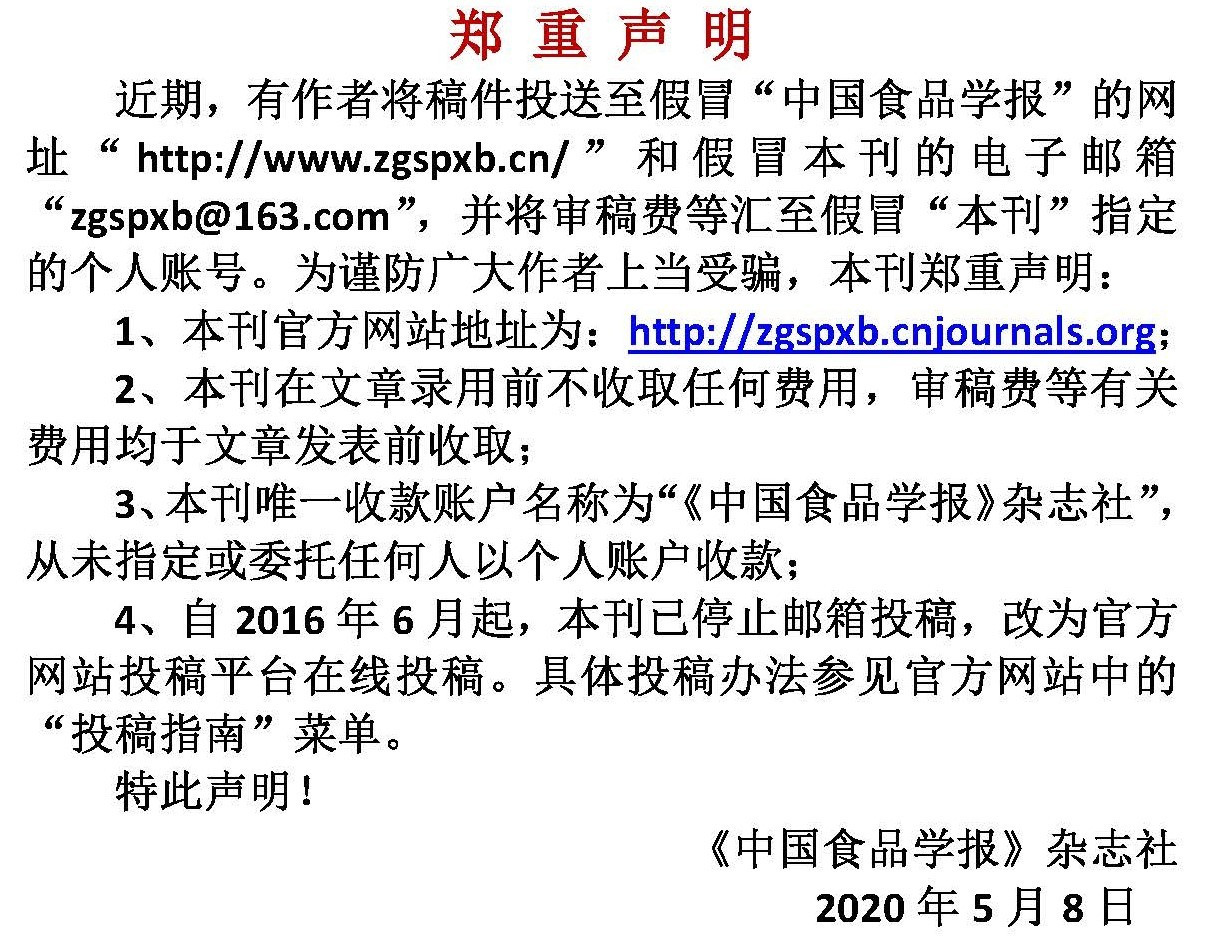

版权所有 :《中国食品学报》杂志社 京ICP备09084417号-4

地址 :北京市海淀区阜成路北三街8号9层 邮政编码 :100048

电话 :010-65223596 65265375 电子邮箱 :chinaspxb@vip.163.com

技术支持:北京勤云科技发展有限公司

地址 :北京市海淀区阜成路北三街8号9层 邮政编码 :100048

电话 :010-65223596 65265375 电子邮箱 :chinaspxb@vip.163.com

技术支持:北京勤云科技发展有限公司